Our Die Bonder series is specifically designed for the high-precision pick-and-place field, supporting advanced processes such as DAF, Dispensing, and FC bonding. We offer comprehensive solutions covering System-in-Package (SiP), microwave components, optical modules, and high-speed memory stacking.

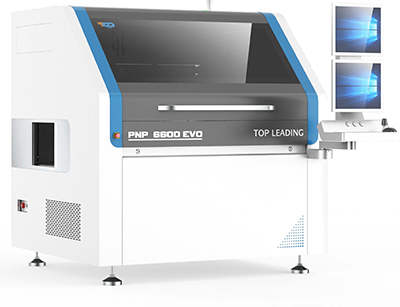

PNP6600EVO — Multifunctional High-Precision Die Bonder

Ultimate Precision for Complex Packaging

- Performance: Achieve placement accuracy of ±5μm@3σ and angular control within ±0.1∘@3σ

- Key Features:

Equipped with a precision air-bearing force control system (10~1000gf) to handle fragile components with care.

Dust-proof design: Standard Class 1000, with an option for Class 100 cleanroom environments.

- Applications: SiP, TR modules, DC/AC, microwave components, and optical modules

PNP6600A — Eutectic Die Bonder

High-Temperature Reliability for Power Devices

- Performance: Accuracy of ±7μm@3σ with a throughput of 1000 CPH.

- Key Features:

Integrated clip-type rail heating system including preheating, heating, and cooling zones.

Supports high-temperature processes up to 450°C.

- Applications: Microwave RF devices, detectors, and high-power LED electronics.

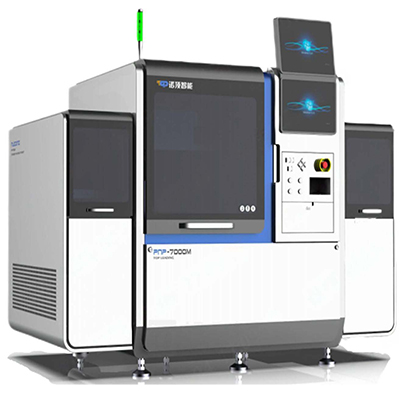

PNP7000M — High-Speed Stacking Die Bonder

Mass Production for Next-Gen Memory

- Performance: Ultra-high throughput of up to 6000 CPH (at 50ms process time) with ±7μm precision.

- Key Features:

Optimized for Logic/Flash/DRAM memory chip stacking.

Compatible with 8" and 12" wafer rings.

- Applications: High-density storage chip stacking and advanced memory packaging.

Technical Specifications at a Glance

| Feature | PNP6600EVO | PNP6600A | PNP7000M |

|---|---|---|---|

| Accuracy | ±5μm@3σ | ±7μm@3σ | ±7μm@3σ |

| Max CPH | 2500 (at ±10μm) | 1000 | 6000 (at 50ms process) |

| Substrate | Max 300*200mm | Max 300*200mm | Max 300*110mm |

| Special Tech | Air-bearing Force Control | 450°C Eutectic Heating | High-Speed Stacking |

| Weight | 1800 KG | 1500 KG | 2300 KG |

Our Core Technology Advantage

Topleading Intel machines are built on Six Core Technologies that ensure long-term stability and high yield:

- Precision Mechanics: Utilizing high-precision platforms and high-speed Pick & Place (P&P) systems.

- Advanced Simulation: Designs are validated through statics, thermodynamics, and vibration simulations to eliminate mechanical errors.

- Software Intelligence: Integrated HMI with AI Large Models for smarter image processing and module decoupling

CONTACT US

HEAD OFFICE

Taoyuan (Taiwan)

Phone: +886-3-3557608

Fax: +886-3-3557205

Email: sales@tekcrown.com

Irvine (USA)

Phone: +1-949-436-3785

Fax: +1-949-536-5392

Email: sales@tekcrown.com