We provide a complete product line for high-precision servo press-fit equipment, primarily focusing on 5G communications, new energy, automotive electronics, and IGBT modules.

Core Product Series

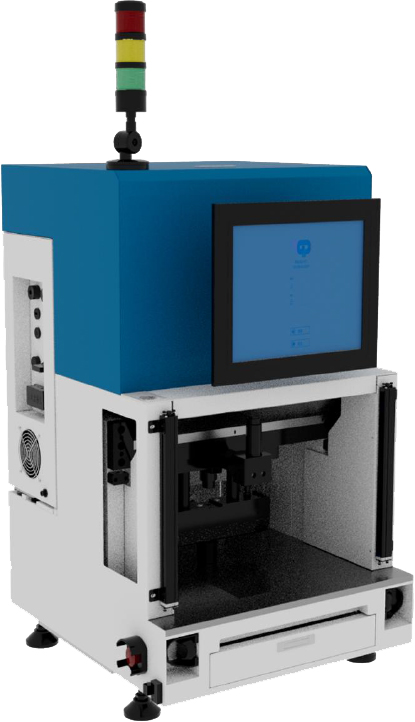

- Model Type MCP-3T

- Press Force 3 Tons

- Max PCB Size 460L x 610W

- AutomationLevel Manual Mold Change

- Best Use Case Small modules|automotive electronics

- Model Type MCP-10T

- Press Force 5 Tons

- Max PCB Size 630L x 800W

- AutomationLevel Manual Mold Change

- Best Use Case Servers|high-force applications

- Model Type SCP-5T

- Press Force 5 Tons

- Max PCB Size 700L x 700W

- AutomationLevel Auto Mold Change

- Best Use Case Mass production with manual loading

- Model Type ACP-3T

- Press Force 3 Tons

- Max PCB Size 800L x 700W

- AutomationLevel Inline Full Auto

- Best Use Case High-volume production with conveyors

Key Technical Advantages

- Superior H-Type Frame Structure: Our machines utilize an H-type structure consisting of two vertical frames and two horizontal bars. This design provides extreme rigidity and resists deformation, ensuring ram verticality and pressing accuracy even for large-scale circuit boards

- Closed-Loop Servo Drive Control: Features a full-process closed-loop servo system that monitors pressure, distance, and speed in real-time. This precise control prevents over-pressing or under-pressing, ensuring high-quality results for delicate components

- Intelligent Bent Pin Detection: Integrated high-precision pressure sensors can detect premature contact with the connector. If a bent or misaligned pin is sensed, the machine stops immediately to protect expensive modules from damage.

- Air-Floating Press Head: Our innovative air-floating design allows for 360° pressing at any angle on the PCB. It utilizes compressed air to create a floating gap, providing automatic correction if a connector is slightly misaligned during entry

- Smart Mold Storage & Recognition: The SCP and ACP series feature a mold rack that stores up to 13 different molds. Each mold carrier has a unique identity recognized by a vision system, reducing line changeover time by 80% and doubling pressing efficiency

- Optional Two-Stage Press Force: Supports a secondary small-force sensor (5-2000N) specifically designed to sense the feedback force as the mold enters the connector, providing total protection for high-end connectors

Industry 4.0 & Digital Management

- User-Friendly Interface: Features a touch-screen interface with multi-language support (Chinese/English). The software is highly intelligent, automatically assigning default parameters based on connector size and required force

- Full Data Traceability: Our systems are Industry 4.0 ready, allowing seamless connection to MES systems. All pressing data curves can be stored locally or uploaded to a server for comprehensive quality tracking and accessory lifespan monitoring

CONTACT US

HEAD OFFICE

Taoyuan (Taiwan)

Phone: +886-3-3557608

Fax: +886-3-3557205

Email: sales@tekcrown.com

Irvine (USA)

Phone: +1-949-436-3785

Fax: +1-949-536-5392

Email: sales@tekcrown.com